TUBITAK-1001 Research Grant

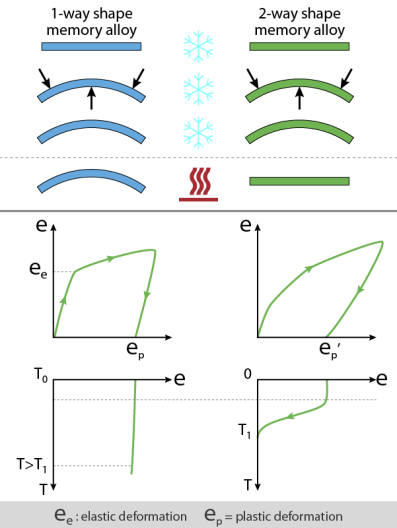

Modeling and Simulation of Thermomechanical Behavior of Shape Memory Alloys

Shape Memory Alloys (SMAs) are genuine materials for shape memory materials which can return to their original shape with phase change at high temperatures in case they subject to large deformations.Because they have a genuine constitution, SMAs are particularly used in high technology applications such as aerospace and biomedical applications. We aim to model coupled thermo-mechanical behaviours of shape memory alloys using large deformation theory of continuum media. NASA (National Aeronautics and Space Administration) is a leading institution having vast test data on modeling SMAs. At the final phase of project, validation and verification of the model will be conducted by the provided experimental data from NASA.